Infrastructure

1) Portable Icing Tunnel

The portanble icing tunnel at IVT faculty of UiT Narvik attributes itself with a test section dimension of 45.7cm × 47cm × 83.5cm and advanced air automizing nozzles producing droplets with MVD range of 20µm—80µm. The distinguishing feature of this icing tunnel is its easy portability for outdoor testing of different models. The maximum achievable wind speed is 10ms-1. The temperature control unit supported with HMI can maintain temperature at any value between -20.0℃ to +30.0℃. Other salient features are as follows:

- Visual support: Digital imagery with live video support using GoPro Camera (with Bluetooth conection), FLIR A615 thermal IR camera (wired connection)

- 2- axis force balance system

- Hardware support: Data-Logger

- Software support: MATLAB, IR Control, Labview

- Spray-Bar System (Heated air automizing nozzel)

|

|

|

|

|

2) Aerodynamic Wind Tunnel

arcICE research group has an open loop wind tunnel supported by a 3-axis balance system to measure lift, drag & pitch of model under observation. This balance system is also interfaced with Data Acquisition System (DAQ System) to directly record pressure readings & aerodynamic forces. Other specifications are as follows:

- Test-section: 30 cm × 30 cm x 60 cm

- Max wind speed: 56ms-1

- Flow visualization (Smoke generator, PIV system)

|

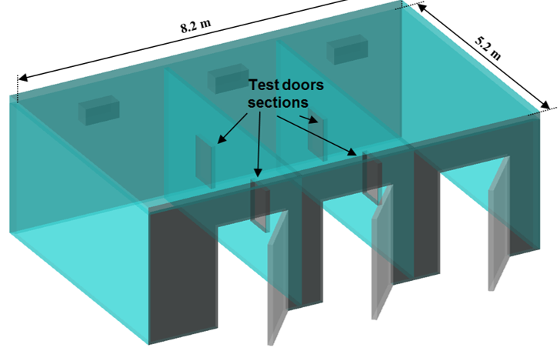

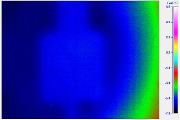

3) Cold Climate Chamber

Cold climate chamber comprises of 3 separate rooms equipped with chillers and frequency controlled ice generators. Cooling system is able to regulate temperature between -20.0℃ to +30.0℃ and is made functional by Human Machine Interface (HMI). All the rooms implement programmable thermocouples, weather sensors etc. CCTV camera and thermal infrared camera are available for live video monitoring. An advanced DAQ system is able to record data from multiple sensors during experimentation.

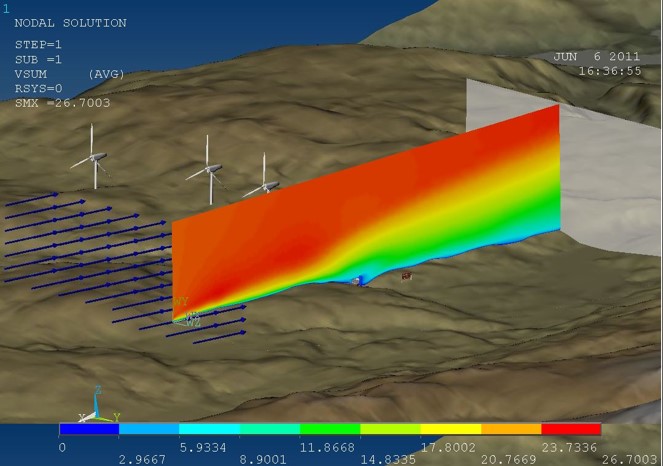

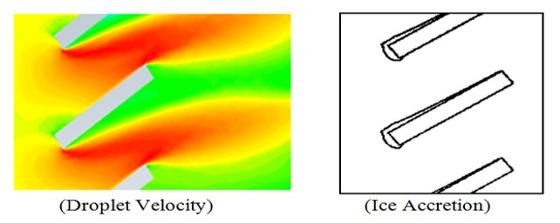

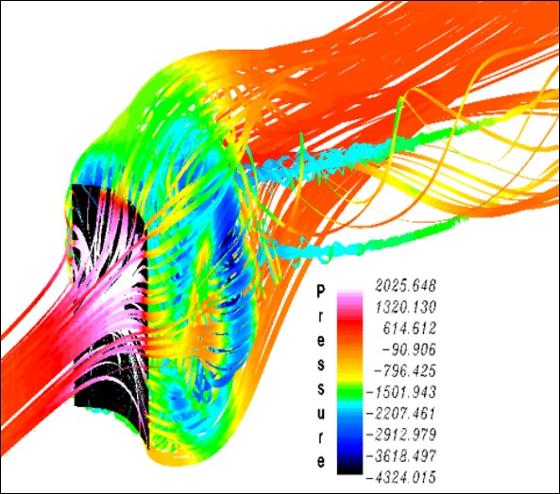

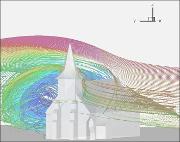

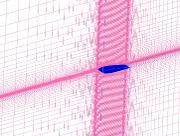

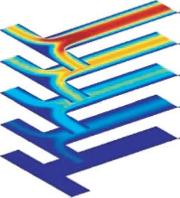

4) CAE Softwares

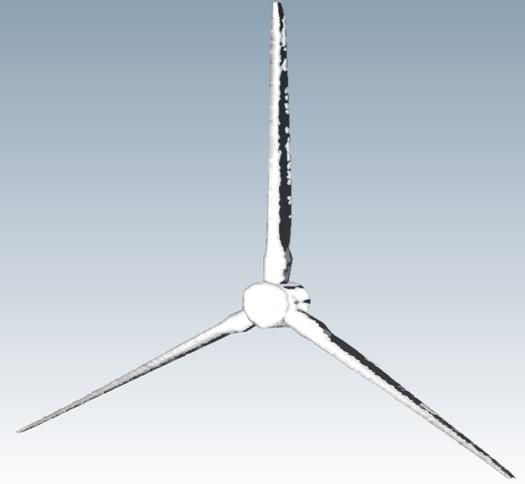

nICE project consortiuim iis equiped with advanced and latest softwares used worldwide for R&D purposes. The available state-of-the-art Computer Aided Engineering (CAE) numerical solvers include:

- Fluent, ANSYS FENSAP-ICE, CFX.

- ANSYS, SolidWorks, Rhino.

- TECPLOT, Pointwise, ICEM-CFD.

- WindSim, Windographer, Global Mapper.

|

|

|

|

|

|

|

|

|

|

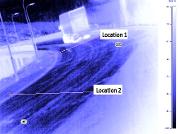

5) Field Ice Monitoring Station

An ice monitoring station is installed by Icing Research Group near Linken tower at Narvikfjellet (located at 1006 m.a.s.l). The objective is to collect longterm metreological dataset for educational & research purposes in order to study ice accretion phhysics and resultant ice loads on structures.

This field ice monitoring station consists of various advance icing sensors, meteorological sensor and dual lens heated web camera that can help us to closely study the ice accretion physics and resultant ice load on structures. Web camera is available for 24-hours monitoring using 4G connection. This field station consists of following sensors.

- Meteorological heated sensor/LUFFT WS500 (Wind speed, direction, temperature, humidity, pressure etc.)

- HoloOptic T44 sensor (ice detection and icing rate) I

- CETROLL sensor/KVT

- ICELOAD Monitor/Combitech (with 30 mm cylinder dia)

- ICELOAD Monitor/Combitech (with 57 mm cylinder dia)

- ICEMET sensor/Oulu University (droplet size & MVD)

- Heated dual lens web camera/KVT 4G data communication setup

|

|

6) Portable Field Spray Bar Icing System

Spray bar system at UiT is a portable, horizontal array spraying mechanism that can be used both indoor & outdoor for icing experiments. It can simultaneously house 6 air automizing sparying nozzles that can produce droplets with MVD 20µm—80µm. Applications of spray-bar system include: ice accretion studies on small or medium size scaled models, effect of air-water proportional variation for ice formation, deicing system development etc.

|

Several experiments have been conducted by research group at UiT using this spray bar system to study icing on airfoil/bridge models and general purpose drones to study ice impact on them.

|

|

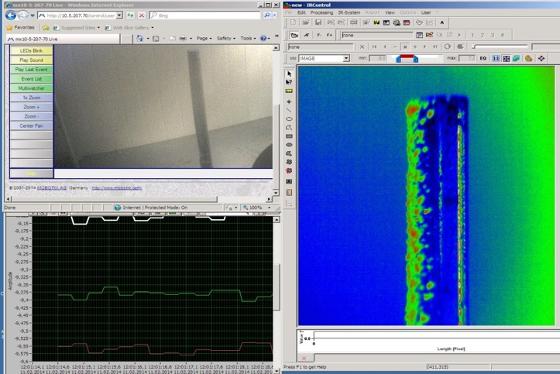

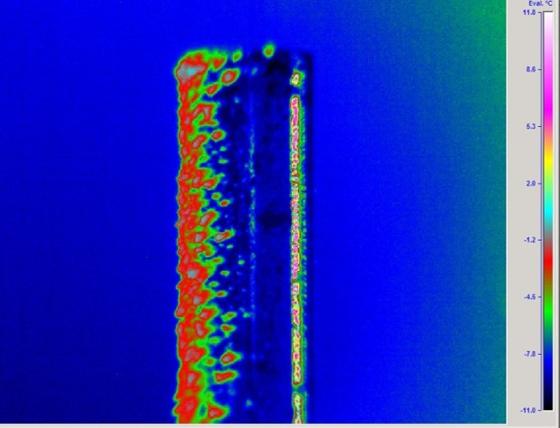

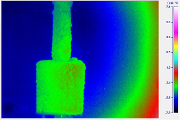

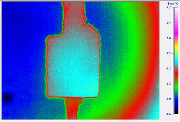

7) Thermal IR Camera Ice Detection System

nICE consortiuim is utilizing its capabilities in devising techniques to identify different icing types based on emissivity and thermal detection. For this purpose FLIR IR cameras modified to sustain subzero icing conditions is being used along with IR Control software utility. The future studies in this arena may lead to reverse engineering i.e.: designing an anti-icing/deicing system after identifying a specific ice type using thermal IR.

|

|

|

|

|

|

|

|

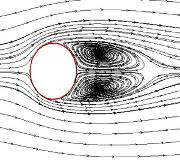

8) Particle Image Velocimetry (PIV) System

arcICE group has an advance PIV system, connected with aerodynamic subsonic wind tunnel. The system can be used to study the complex flow behavior for various applications.

.png)